If you’re designing a new piping system or planning maintenance, you’ll likely consider different flanges. The raised face slip-on flange is a common, reliable, and cost-effective choice for many applications. This guide explains what it is, where to use it, and how to work with it.

What is a Raised Face Slip-On Flange?

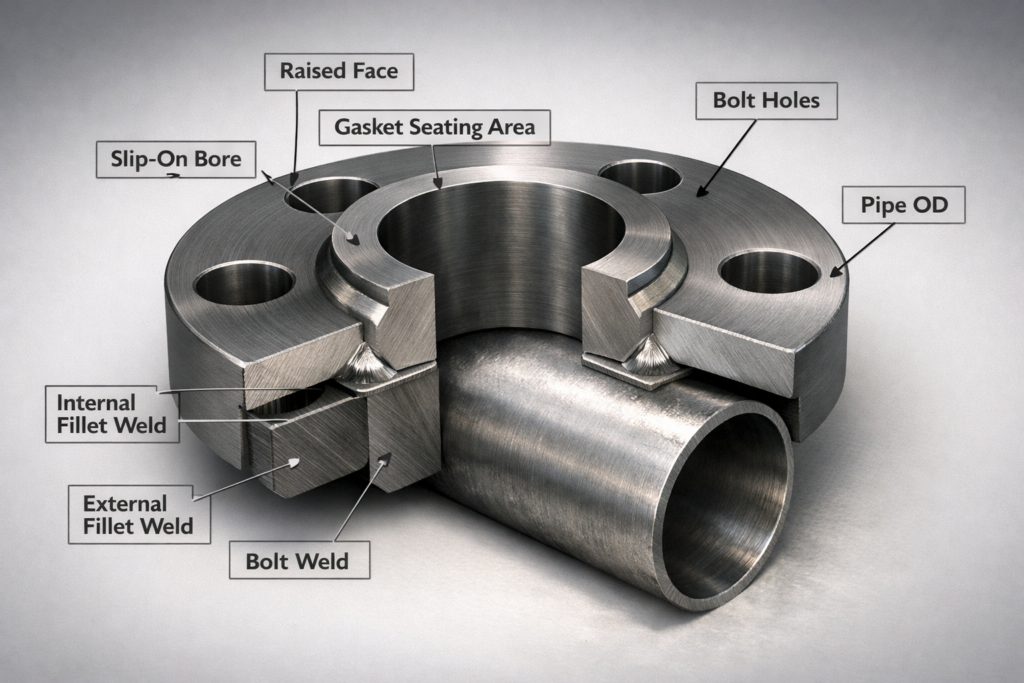

A raised face slip-on flange (often abbreviated as RFSO or SORF) has two defining features:

- Slip-On Design: It has a low hub with a bore slightly larger than the pipe’s outer diameter. You slide the flange over the pipe and then secure it with two fillet welds, one inside the hub and one on the outside.

- Raised Face (RF): The sealing surface is a raised, flat ring around the bore. When two raised face flanges are bolted together, this creates a concentrated contact area for the gasket, improving the seal.

Its main job is to create a strong, leak-resistant connection between pipes, valves, or equipment that can be assembled and disassembled with bolts.

Key Specifications and Dimensional Data

Raised face slip-on flanges are manufactured to strict dimensional standards like ASME B16.5 to ensure parts from different suppliers are compatible. The “raised face” is a standard feature: for Class 150 and 300 flanges, it is typically 1/16 inch (1.6 mm) high. For higher pressure classes, the face height increases to 1/4 inch.

Here is a reference table of standard dimensions for ASME B16.5 Class 150 raised face slip-on flanges for common sizes.

| Nominal Pipe Size (NPS) | Flange Outer Diameter (O) | Flange Thickness (T) | Bolt Circle Diameter | Number of Bolt Holes |

| 1/2″ | 3.50 in | 0.38 in | 2.38 in | 4 |

| 2″ | 6.00 in | 0.69 in | 4.75 in | 4 |

| 4″ | 9.00 in | 0.88 in | 7.50 in | 8 |

| 6″ | 11.00 in | 0.94 in | 9.50 in | 8 |

| 8″ | 13.50 in | 1.06 in | 11.75 in | 8 |

| 12″ | 19.00 in | 1.19 in | 17.00 in | 12 |

Note: Dimensions are in inches. Always consult the full ASME B16.5 standard or a supplier’s specification sheet for complete data, including bore sizes and tolerances.

When to Use a Raised Face Slip-On Flange

Choosing the right flange depends on your system’s needs. The chart below outlines the ideal use cases for RFSO flanges and when another type might be better.

Applications: RFSO flanges excel in systems like plant water lines, cooling systems, low-pressure steam, HVAC, fire protection sprinkler lines, and other general utility services.

Pros and Cons:

- Advantages: They are easier to install and align than weld neck flanges, have a lower initial cost, and their design provides a good seal for many industrial uses.

- Limitations: The double fillet weld is not as strong as a weld neck’s butt weld. They are not recommended for high-pressure, high-temperature, or highly cyclic services where fatigue is a concern. They are also not suitable for hazardous gases or fluids where leak integrity is paramount.

Frequently Asked Questions

Q: What is the correct welding procedure for a slip-on flange?

A: The pipe end should be set back from the flange face by the pipe wall thickness plus about 1/8 inch. This allows for a proper internal fillet weld. A second external fillet weld is then made where the pipe meets the back of the flange hub.

Q: Can I use a slip-on flange for high pressure if I specify a Class 600 or higher rating?

A: While a Class 600 flange body is rated for higher pressure, the inherent weakness remains in the fillet weld connection. For true high-pressure or high-stress systems, a weld neck flange is the standard, safer choice.

Q: What’s the main difference between a slip-on and a lap joint flange?

A: A slip-on flange is one piece welded to the pipe. A lap joint flange is a two-part system: a stub end (welded to the pipe) and a loose backing flange. The lap joint design allows the flange to rotate for easy bolt hole alignment, making it ideal for systems that need frequent disassembly.

Q: What materials are available?

A: They are commonly made from carbon steel (ASTM A105), stainless steel (304/316), and various alloy steels to match the pipe material and resist corrosion from the process fluid.

Q: How do I ensure I order the correct flange?

You must specify several key details:

- Nominal Pipe Size (NPS)

- Pressure Class (e.g., 150, 300)

- Flange Type (Slip-On)

- Facing (Raised Face, RF)

- Material Specification

- Relevant Standard (e.g., ASME B16.5)

Conclusion

The raised face slip-on flange is a practical, economical solution for a wide range of standard industrial piping applications. Its ease of installation and reliable performance make it a staple in non-critical, low to medium-pressure services. Success depends on selecting the correct pressure class and material for your operating conditions and ensuring proper welding during installation.

Need to source reliable raised face slip-on flanges for your next project? We supply standard and custom RFSO flanges in all pressure classes and materials, with full traceability and dimensional accuracy to ASME B16.5 standards.

Submit your detailed specifications for a precise quote and technical data sheets: http://texasflange.com/lp12/